Manufacturing

From initial design to sourcing & manufacturing, we develop our clients’ vision to the highest possible standards. We are experts in design development & private label production and we have an enormous and varied supply base with a network of industry partners throughout Europe, UK, the Middle East & Asia.

Design

We are experts in design development & private label production and we have an enormous and varied supply base and a very strong network of industry partners throughout Europe, UK, the Middle East and Asia, allowing us to develop our clients’ vision to the highest possible standards.

Trend & Market Research

Moodboard

Colour Range Development

Product or Garment Design (usually 3-4 drafts)

Collection Range Plan

Print or Pattern Design (optional)

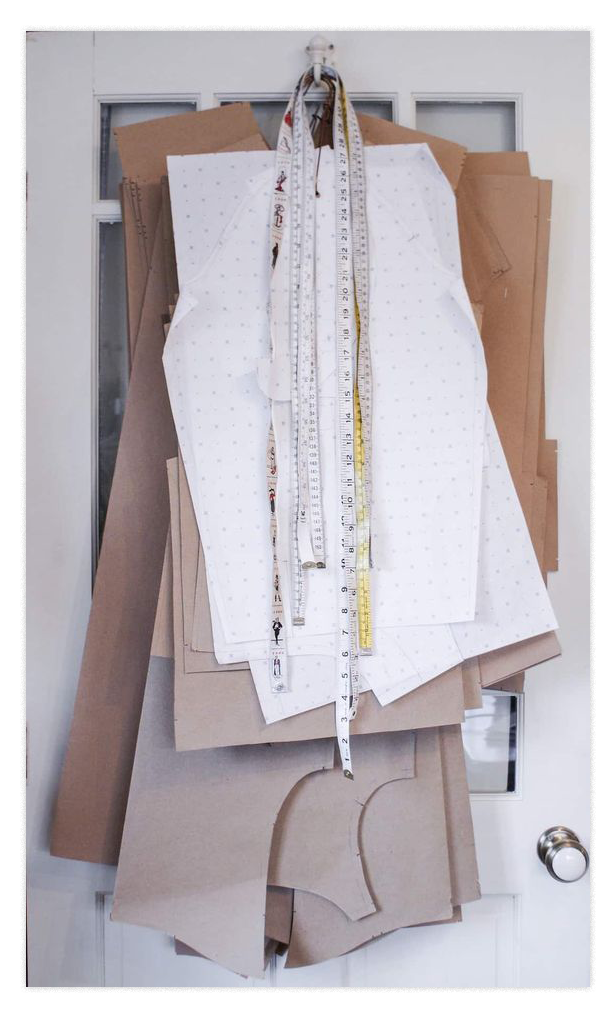

Tech Packs (Technical Specifications)

A tech pack is probably the most important document when producing your collection. It shows the specific details behind a garment’s design & construction and serves as a blueprint to communicate your vision to the manufacturer.

Technical Drawings

Garment Description

POM (Point of Measurements)

Pantone Colour Breakdown

BOM (Bill of Materials)

Tags (Neck labels, size labels, wash care labels,hang tags)

Global Production Facility Sourcing

We work with 100’s of facilities globally and locally but your ideal production facility sourcing will depend on a lot of factors- such as

Your MOQ (minimum order quantity)

What the factories specialise in- is there ususal product range capability suitable for your brand needs?

Can they work within the timeframe that you need the goods produced and delivered within?

Can they work with the fabrics you have decided to go with?

Can they work within the target cost prices that we have given them?

The negotiations with factories can be complex and exhaustive, but with our 20 years of experience, you will not need to worry, as we will take care of all of this for you and come back to you with the top options that we feel suit

your brand and budget correctly.

Global Fabric Sourcing

Fabric Sourcing will be ongoing from earlier discussions and our team will advise and collaborate with you on what you want for your collection, what the ideal fabrics and compositions for each style will be and what is possible within your target cost price. Then we will source as many fabric swatches as possible for various suppliers and factories, which will be sent to you for final approval after our team have reviewed them and again made suggestions as to what will work best for your collection.

Sample Production Management

Then we are onto the sampling process, During this time the MGC team will handle all of the correspondance with the factories, whilst giving you regular updates on what the progress is. Each time a change is made in a sample, the tech pack then needed to be amended accordingly also, and resent back to the factory for the next round of sampling until you are 100% happy.

Bulk Manufacturing & Production Management

The bulk manufacturing process usually takes between 45-60 days again depending on a lot of variables such as-colours dyed, fabric printed etc, Once bulk production begins, we will be in contant with the factory to ensure all is going as planned and that time-lines are being met to ensure there are no issues that may delay delivery.

Quality Control Report Analysis

Here at MGC- we take a three tiered approach to Quality control to ensure there are no issues, as once your product leaves the factory, there is usually no comeback if something arrives that is incorrect. That is why it is so important that you have professional guidance all the way through the design, sourcing and production process as it is easy to miss something if you are not experienced in the industry. We request the internal reports from the factories and suppliers, our job is to read them and report if anything is off, we also encourage our clients to test and wash all sample products themselves and we will advise on what to check, we also prefer to get a set of samples sent to us inhouse from the production line so that we can also check general QC and most importantly, we ALWAYS encourage our clients to get external third party QC from a reputable company which we can advise on ,to check everything from the fabrics through the entire production process as this is the only way to trully ensure that you production is ready to leave the factory.

Logistics & Shipping Management

Shipping and logistics for a fashion brand can be a complex process, but we are here to handle everything along the way for you. There are many shipping methods to choose from, such as air, sea, road, or rail freight.